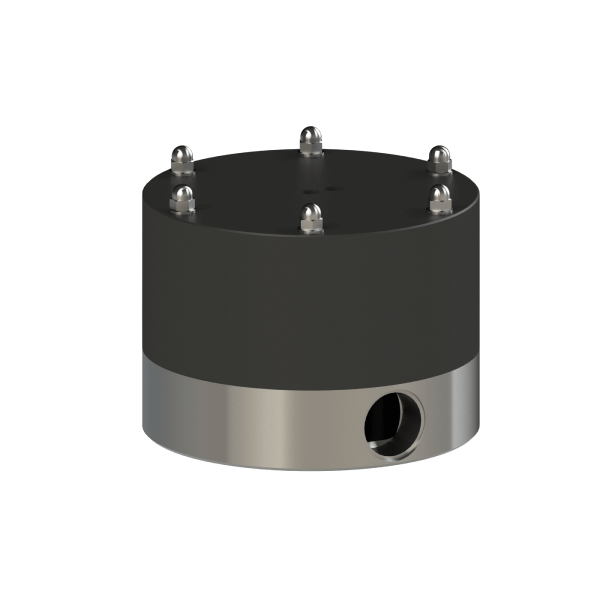

In-line pulsation dampener

STEADO offers a range of in-line pulsation damper designs, customized to suit the unique demands of various industrial applications.

FOR ALIMENTARY AND PHARMACEUTICAL APPLICATIONS

STEADO offers the “L” series pulsation dampers, specifically designed for food, beverage, and pharmaceutical applications. This advanced design completes our comprehensive range of pulsation dampers tailored to meet the stringent requirements of these critical industries.

Key features of the new in-line shock absorber include:

- No limitation on nitrogen gas charging pressure: The charging pressure inside the bladder of the pulsation damper must be 80% of the pump’s working pressure.

- FDA-approved rubber tube: The rubber tubes, made from EPDM or silicone, are certified for food and pharmaceutical applications, ensuring safety and compliance.

- Customizable food and pharmaceutical connections: We adapt the connections to suit the specific needs of your system, including requirements for food and pharmaceutical processing.

- Designed for easy cleaning: With a corner-free design, the pulsation damper facilitates effective cleaning. The design ensures that no product is retained, making it ideal for CIP (clean-in-place) processes.

- No water hammer effect: The internal passage section is consistent with the connection section, preventing any reduction in fluid passage. The tube or double rubber tube expands during normal operation, rather than being compressed by the gas charging pressure, which eliminates the water hammer effect.

- Efficient liquid occlusion management: Under operational conditions, any internal occluded liquid remains in the chamber between the tube or double rubber tube and the lower cylinder. The bladder is stretched, and the button rests on the lower part, ensuring that the gas pressure does not affect the intermediate liquid chamber.