Get Professional Help

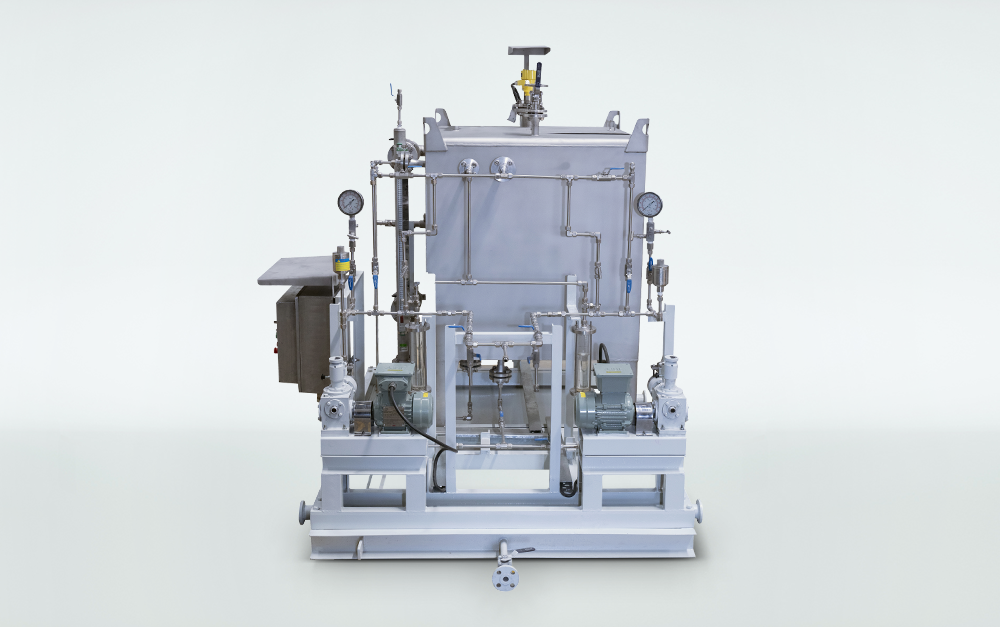

Chemical Reactor Agitator

At STEADO, we understand the vital role agitation plays in achieving efficient and successful chemical reactions. As a trusted manufacturer of high-performance chemical reactor agitators, STEADO is committed to delivering solutions that optimize your processes and boost productivity. In the demanding world of chemical production, we focus on enhancing reaction efficiency, improving mixing performance, and maximizing your yields—every step of the way.

Unparalleled Expertise in Chemical Reactor Mixing:

Our team of highly skilled engineers at STEADO possesses in-depth expertise in chemical reaction processes and fluid dynamics. This specialized knowledge empowers us to design and manufacture agitators that:

-

Enhance Reaction Rates

Our agitators generate optimized flow patterns and shear forces within the reactor, ensuring thorough reactant mixing. This accelerates reaction times and boosts conversion rates, improving process efficiency. -

Combat Mass Transfer Limitations

STEADO agitators eliminate mass transfer barriers through uniform mixing. This maximizes reactant interaction, supports complete reactions, and reduces the formation of unwanted byproducts. -

Maintain Process Uniformity

With consistent agitation across the entire reactor volume, STEADO solutions prevent stratification and localized concentration gradients—ensuring steady, high-quality product output. -

Optimize Heat Transfer

Proper agitation plays a critical role in heat exchange. Our designs promote efficient heat transfer between the mixture and reactor walls, enabling precise temperature control and enhanced process stability.

Custom-Designed Agitation Solutions for Every Process

Tailored Engineering by STEADO

At STEADO, we recognize that every chemical process is unique. That’s why we specialize in delivering fully customizable agitator solutions engineered to meet your precise application requirements. Our design process incorporates a comprehensive set of factors to ensure optimal performance and durability in any environment.

Reactor Geometry and Size

We engineer agitators to seamlessly fit the geometry and volume of your reactor vessel, ensuring efficient mixing across the entire batch. Whether your reactor ranges from a few liters to several thousand liters, STEADO designs with precision to match your scale and configuration.

Chemical Properties

Our agitator designs are driven by the physical and chemical properties of your reactants—including viscosity, density, and reactivity. We select impeller types accordingly, using high-grade materials such as SS316, Hastelloy, or Teflon-coated alloys. Power requirements are optimized, with motors typically ranging from 0.5 HP to 75 HP, depending on process needs. The complete agitator system is built using corrosion-resistant materials suited for both general and aggressive chemistries.

Desired Mixing Intensity

From gentle blending to high-shear, high-turbulence applications, STEADO engineers configure each agitator to achieve the exact mixing intensity required. Our systems support a wide range of operating speeds—from 50 RPM to 1500 RPM—to accommodate everything from delicate emulsification to rapid dispersion and homogenization.

Operating Conditions

We design our agitators to perform reliably under the toughest conditions. Our solutions handle pressures up to 10 bar and temperatures up to 300°C, with custom seals, shaft sleeves, and coatings available for abrasive or corrosive environments. For processes involving solids, we offer reinforced impellers and abrasion-resistant components to maximize service life and minimize maintenance.

Engineered for Performance and Reliability

Precision-Built Agitators by STEADO

At STEADO, we are committed to delivering agitator systems that embody engineering excellence, durability, and consistent performance. Every component we design and manufacture is driven by quality and innovation.

Advanced Design Techniques

Our engineers use Computational Fluid Dynamics (CFD) simulations to refine impeller geometry and predict flow behavior within reactors. This ensures optimal mixing efficiency, energy utilization, and process consistency from the start.

Precision Manufacturing

With access to state-of-the-art manufacturing infrastructure, STEADO produces each agitator using advanced machining, welding, and fabrication technologies. Every component is built to exacting tolerances for maximum reliability and extended service life.

Premium Materials

STEADO offers a diverse selection of high-performance materials tailored to your process requirements. Choose from Stainless Steel (SS304/SS316), Hastelloy, and other corrosion-resistant alloys suited for aggressive or specialized environments.

Diverse Applications Across the Chemical Industry

Versatile Agitation Solutions by STEADO

STEADO agitators are trusted across a broad spectrum of chemical processes, delivering precise, reliable mixing for even the most demanding applications. Our equipment is engineered to adapt seamlessly to your process needs—enhancing reaction efficiency, safety, and product quality.

Fine Chemical & Specialty Material Production

Precise mixing is vital for applications such as catalyst synthesis, where uniform particle distribution directly impacts reaction efficiency and product purity.

Polymerization Reactions

STEADO agitators ensure consistent blending of monomers and catalysts, enabling complete conversion and maintaining high polymer quality standards.

Hydrogenation Processes

Our agitators support optimal gas-liquid dispersion, ensuring efficient and uniform distribution of hydrogen gas—resulting in improved reaction rates.

Nitration Reactions

Controlled agitation is critical for the safe and effective handling of exothermic reactions, ensuring steady reactant contact and temperature control.

Sulfonation Reactions

Effective mixing facilitates complete contact between reagents, improving the yield and selectivity of sulfonic acid group incorporation.

Oxidation Reactions

STEADO agitators enhance oxygen transfer throughout the reaction mixture, optimizing oxidation efficiency and product consistency.

Neutralization Processes

Our systems deliver thorough mixing of acidic and basic solutions, supporting accurate pH control and full neutralization during synthesis.

Crystallization Processes

With controlled agitation, crystal growth is uniform—ensuring desired crystal size distribution and superior product quality.

Reactions Involving Solids

Our anchor-type agitators with scraping blades are ideal for suspending solids and preventing settling—essential for reactions involving solid catalysts or heavy particulates.

Distillation & Extraction

Agitation enhances mass transfer between immiscible phases, improving the efficiency of separation and solvent recovery.

Heat Transfer Applications

Proper mixing facilitates uniform temperature distribution and efficient heat exchange, critical for maintaining optimal reaction conditions.

Unparalleled Quality and Reliability

Precision. Durability. Excellence.

At STEADO, quality isn’t just a benchmark—it’s the foundation of everything we do. Every chemical reactor agitator we produce undergoes stringent quality control and performance validation to ensure superior reliability under the most demanding conditions. From premium materials to high-precision components, STEADO agitators are built for long-lasting, consistent operation in complex chemical environments.

Client-Centric Approach

Your Process, Our Priority

At STEADO, we believe in more than just providing a product—we build partnerships. Our client-first approach ensures that your specific needs are heard, understood, and fulfilled at every stage: from initial consultation and custom design to post-installation support. We are committed to your operational success.

Why Choose STEADO?

-

Innovation

Embracing the latest in engineering tools, simulations, and process design. -

Customization

Agitation systems designed specifically for your process goals and materials. -

Quality

Uncompromising standards for reliability, performance, and material integrity. -

Support

Expert technical assistance and responsive service at every stage. -

Sustainability

Solutions aligned with environmentally responsible practices.

Choose STEADO to transform your chemical processing efficiency. Reach out today to discover how our engineered agitation solutions can elevate your operations.

Discover the Science of Mixing

Performance-Driven Engineering

STEADO offers mixer agitators in a variety of designs, sizes, and configurations, tailored to match your unique process requirements. Each unit undergoes strict performance testing to ensure zero defects and maximum output.

Our commitment to engineering excellence has earned us a solid reputation in delivering agitators for diverse industrial applications with consistent results.

Talk to Our Agitation Design Experts

Understanding critical parameters ensures the right solution for your process. Our team will guide you through:

- Tip Speed

- Pumping Capacity

- Detention Time

- ChemScale Calculations

- Velocity Gradient

- Torque Requirements

- Specific Power Consumption

- Material of Construction (MOC)

Agitator Manufacturing Champions

Built for Precision. Proven in Performance.

We maintain the highest standards in machining and fabrication:

- CNC, VMC & Lathe Machine Capabilities

- Approved Welding Standards & Procedures

- Accurate Fabrication with Strict Tolerance Control